Wittenstein Alpha

GALAXIE® DRIVE SYSTEM

FUNDAMENTALLY NEW OVERALL CONCEPT

Technology pioneers at WITTENSTEIN have subjected drive

concepts to a fundamental reassessment. The outcome

is a brand new gearhead generation which is fused with an

innovative high speed motor and optional Industry 4.0

connectivity.

The revolutionary Galaxie® Drive System

reaches performance levels which, up to now, seemed

utterly impossible.

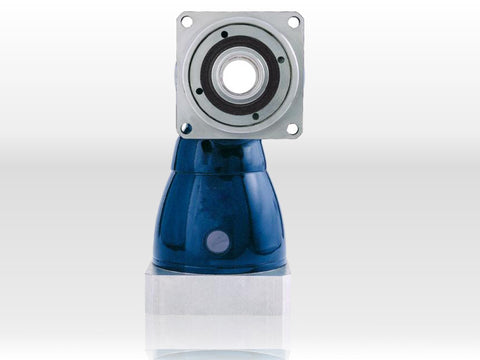

From line to surface contact

The innovative core of the new Galaxie® Drive System is the

almost full surface contact during power transmission. This

gives a tooth contact surface which is six-and-a-half times

larger compared to conventional involute teeth with typical

linear contact. The kinematics are fundamentally new: the

gearhead is the only one of its kind in the world to guide a

large number of individual teeth along an internal ring gear.

The tooth geometry corresponds to a logarithmic spiral

which allows power to be transmitted by the multiple teeth

in surface contact.

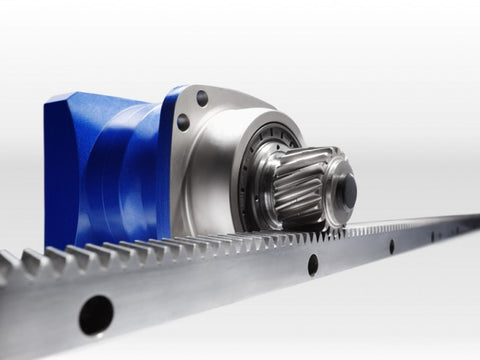

Next Technology Drive

The Galaxie® Drive System leads to a combination of

specifications that were hitherto unattainable: the gearhead

boasts zero backlash – even at the zero crossing – while

retaining full stiffness. Since the teeth follow a logarithmic

spiral, optimal synchronization accuracy is ensured. The

system’s performance features are all significantly better

than those of traditional hollow-shaft drives with the same

outer diameter.

NEW OPPORTUNITIES FOR HIGH PERFORMANCE ENGINEERING

Several WITTENSTEIN customers have been using the

Galaxie® Drive System since 2012. They have all reported a

dramatic increase in productivity thanks to its outstanding

characteristics:

The system significantly extends the life of machine tools

because it unites permanent freedom from backlash with

extreme stiffness and precision.

Higher cutting speeds and feed rates are possible as a

result. There is also a clear improvement in manufacturing

quality.

The moving cutting heads required for machining are only

half the normal size, and more compact and power dense

machines are no longer a problem.

The new Galaxie® Drive System excites considerable enthusiasm

among the developers and engineers responsible

for the A, B and C axes of precision machines or for wafer

handling axes; it is ideal whenever precise rotational

movements

and very high forces are essential but space

is limited.

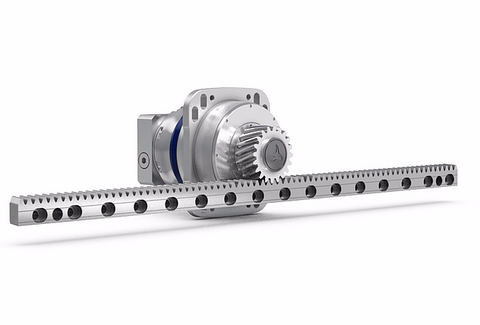

A NEW DIMENSION IN POWER

Up to 91% efficiency has been measured for the Galaxie®

Drive System – far better than for any comparable system.

Efficiency*:

+18 to +29%

The high overload capability is the outcome of the Galaxie®

Drive System’s kinematics, with many individual teeth in

contact and an area six-and-a-half times as large for transmitting

the torques.

Emergency stop torque*:

+150 to +300%

Almost all of the Galaxie® Drive System’s teeth participate

in the torque transmission process, contributing to the

stiffness. Enormous torsional rigidity results.

Torsional rigidity*:

+340 to +580%

Any other type of gearhead would have to be built two, if

not three, sizes bigger to get the same torques as with the

Galaxie® Drive System.

Maximum torque*:

+70 to +170%

The Galaxie® Drive System sets a new benchmark for

extreme

compactness and very high dynamic precision

with alternating loads. It creates totally new productivity

opportunities for high performance engineering. It is now

up to engineers and designers to make real developmental

leaps.

Hollow shaft / outer diameter*:

+3 to +70%

The design principle on which the Galaxie® Drive System is

based allows a very large hollow shaft diameter in relation to

the outer diameter.

Zero backlash

The Galaxie® Drive System can even be realized with

zero backlash by selecting the parts accordingly

Ready for Industry 4.0

Optional sensors enable the Galaxie® Drive System to be

designed with Industry 4.0 connectivity

E-mail: Hi-Tech@medital.co.il

Company Tel: 073-2000280

Omri Dror

Mobile: 054-8128056

E-mail: omri.d@medital.co.il

Direct Tel: 073-2000223

Ronen Sagi

Mobile: 054-6319985

E-mail: ronen@medital.co.il

Direct Tel: 073-2000231

Din Kosberg

Mobile: 054-3826374

E-mail: din@medital.co.il

Direct Tel: 073-2000245

Avihai Ben Naim

Mobile: 054-6707555

E-mail: avihai@medital.co.il

Direct Tel: 073-2000227